yapCAD

Welcome to yapCAD, yet another procedural CAD and computational geometry system, written in Python. This project is still in a pretty early state, though we hope you will find it useful.

Note

yapCAD was created to solve some fairly specific problems in procedural CAD and parametric design , and at present is most developed for generating 2D drawings in the AutoCad DXF format. If you don’t know what procedural CAD or paramaterized design might be useful for, this may not be the tool for you.

On the other hand, if you are tired of manually editing your CAD files whenever you change the thickness of a material, the size of a pipe fitting, or the diameter and spacing of bolts, etc., this might just be the tool you are looking for.

For an example and discussion of what parametric design is and why it might be useful see What is Parametric Design? below.

Much of the documentation for yapCAD can be found in the

README files, as well as in the yapcad.geom module

documentation linked below.

Contents

Indices and tables

What is Parametric Design?

Parametric design is a generalizable approach to solving design problems by means of parameters and algorithms, as opposed to the creation of static drawings or models. Put another way, a conventional design is like a drawing, and a parametric design is like a piece of software that you configure to create the specific drawing that you want.

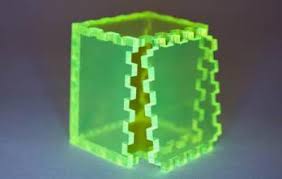

the acrylic box: a parametric design example

For example, imagine that you wanted to design a decorative acrylic box to be assembled from pieces cut from a sheet of material of uniform thickness. This box will be a squeeze-fit design, so that it assembles like a 3D jigsaw puzzle, without the need for additional glue or fasteners.

You might decide on the dimensions of your box, and a scheme by which you cut the edges to create tabs and slots so that when cut, the box will fit together just so. However, the depth of your tabs and slots will necessarily depend on the thickness of the material, which might vary slightly from sheet to sheet, or vendor to vendor. Furthermore, your cutting tool (perhaps a laser cutter) will create a kerf, or width of cut, that vary from machine to machine and with depth of focus.

Finally, your box might be sized to hold a variety of contents, which themselves might vary in size and shape.

One approach is to create a conventional design. You could draw your design for one size of box, material, and thickness of cut, and then hope you have your tolerances correct. If there is a problem, or you want to change box dimensions, you will need to go back and revise your design. Each time you revise, you are essentially redoing the entire drawing from scratch.

Alternately, you could create a parametric design, in which the desired length, width, and height of the box are input parameters, along with the thickness of the material and an estimate of the kerf. Creating a parametric design system might be a bit more difficult than creating a conventional drawing, but once you are done you will be able to generate the design for any desired box, from any desired material thickness, with any kerf, simply by changing a few numbers – automatically, and without having to revise any code or drawing.

Note

For a yapCAD solution to this particular problem, see the

boxcut example in the examples directory

This ability to solve for an entire family of related design problems with a single parametric design system is what gives this approach it’s power and flexibility. For anyone who has spent hours re-drafting a drawing to accommodate minor variations in requirements, this can be an impressive force multiplier on productivity.